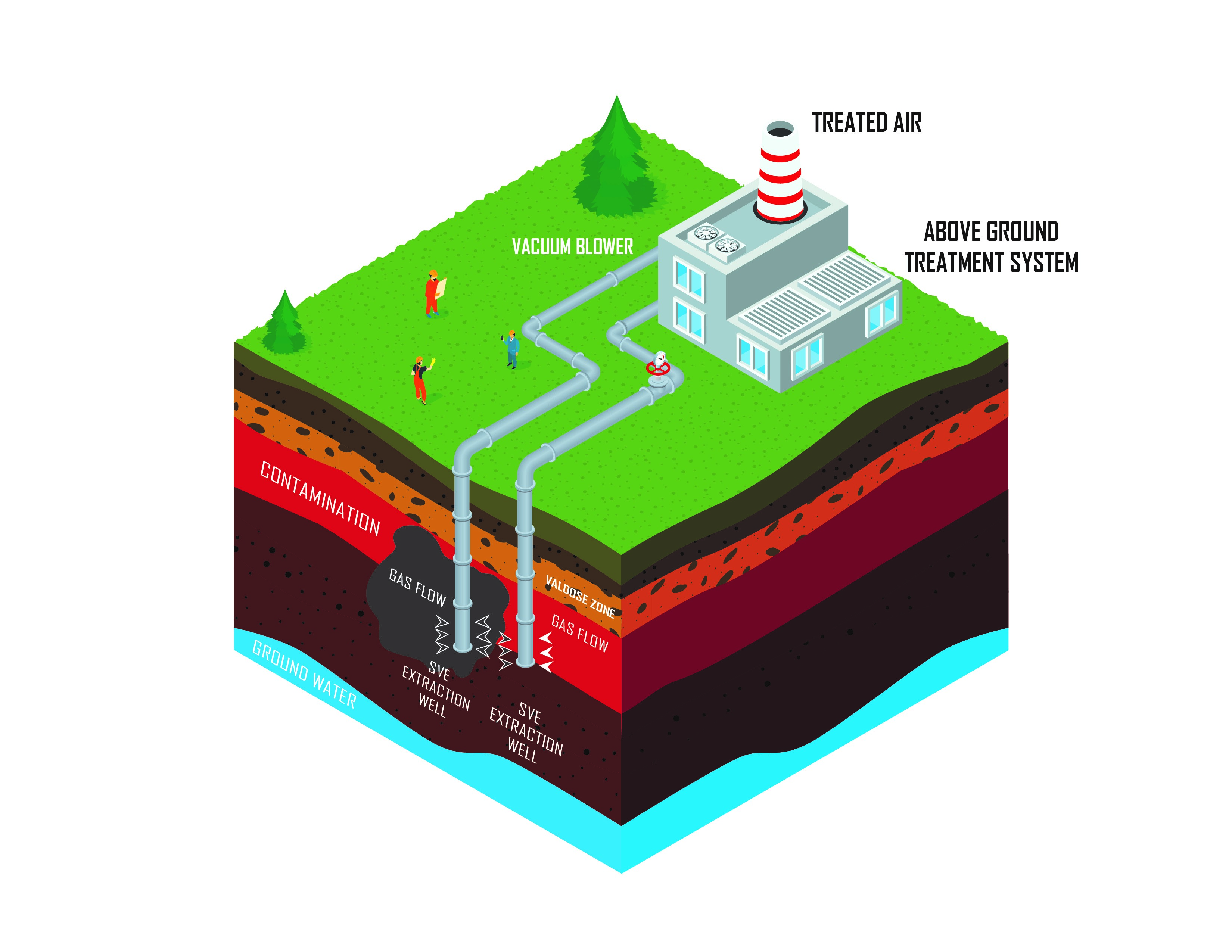

Soil vapor extraction (SVE) is a physical process used to remove chemicals from the soil’s vadose zone of a subsurface environment. This in-situ remediation method can be an extremely effective weapon in the environmental remediation specialist’s arsenal. SVEs selection for use is particularly relevant for chemicals that have high Henry’s Law constants including chlorinated solvents such as perchloroethene (PCE) and trichloroethene (TCE) and many petroleum hydrocarbon compounds such as benzene, toluene, ethylbenzene, and xylenes (BTEX). In addition to the primary mechanism that involves the mass transfer of contamination from the solid and liquid phases to the gas phase, there is at least one additional advantage that SVE creates; the introduction of oxygen into the environment. The introduction of oxygen can enhance the growth of naturally occurring indigenous micro-organism that drive natural remediation by utilizing the contamination as a source of food and thereby further reducing the mass of contamination. SVE technology is also used in conjunction with other remediation technologies that generate contaminant-laden air that needs to be removed or captured (air sparging, electrical resistance/thermal conduction heating).

SVE Installation

An SVE system involves installing one or more extraction wells located in the area to be remediated. The extraction well (or wells) is then connected to a vacuum pump. The vacuum is then applied to the extraction well causing vapor in the soil to be removed from the subsurface. Once above ground, the contaminated air commonly needs to be treated to prevent the contaminants from impacting the atmospheric air. Common treatment technologies for this offgas are carbon absorption, catalytic or thermal oxidation.

SVE Application

The SVE technology is most effective in dry soil. Initial SVE operations are sometimes run at lower than designed vacuums to enhance the desiccation process. The technology is most effective with chemicals boiling points lower than 250° C, chemicals with vapor pressures higher than 0.5mmHg, and chemicals with Henry Law constants greater than 100 atmospheres. The technology is best used in subsurface geologies that have higher permeability such as sandy soils and fractured bedrock. The technology will work in soil that contains higher levels of silt and small amounts of clay. In these types of soil, process design may incorporate higher numbers of extraction wells and more powerful vacuum pumps. In general, the technology is not considered effective in clay soils without some sort of permeability enhancement application (pneumatic or hydraulic fracturing).